Outstanding quality

TK Elevator's retrofit solution provides peace of mind and merits your trust.

Value proposition

TK Elevator's retrofit solution saves you time and delivers a higher return on investment.

Enhanced satisfaction

TK Elevator's retrofit solution enables you to experience a more enjoyable lifestyle.

- TK Elevator’s EBF technology ensures your safety and wellbeing.

- In case of unexpected power failure, emergency leveling device enables the elevator to open the door at the nearest floor to prevent passengers from being trapped.

- Our innovative micro switch stroke amplification enlarges the brake micro switch stroke by 6 times, enhancing the reliability of brake action.

- The UCMP car accidental movement protection, anti-forced door-opening design, and fault self-diagnosis feature mitigate safety hazards, providing users with enhanced safety protection.

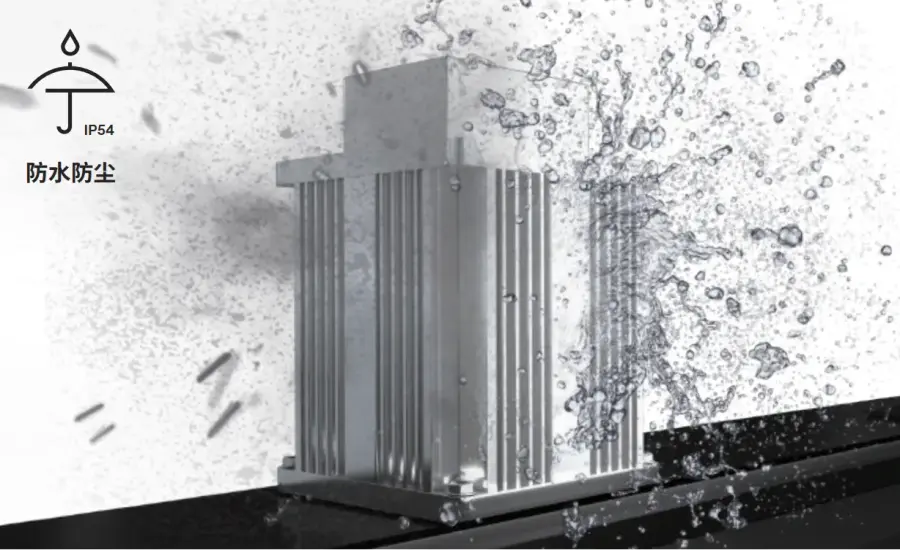

- The door motor is dust- and water-proof (Grade IP54 ), and comes standard with a mechanical lock for the car door.

- By embracing TK Elevator's globally standardized design and manufacturing protocols, this product complies with the stringent German TKE_HSG safety standards, surpassing both our national and European standard prerequisites.

- Meticulously chosen materials and components, such as the mainframe and traction rope with a high safety design factor, along with high-spec guide rails, ensure top-notch quality and safety standards.

- The Internet of Things functionality ensures that your elevator remains under the oversight of government departments.

- Elevator calls via IC card help deter unauthorized use by unidentified individuals.

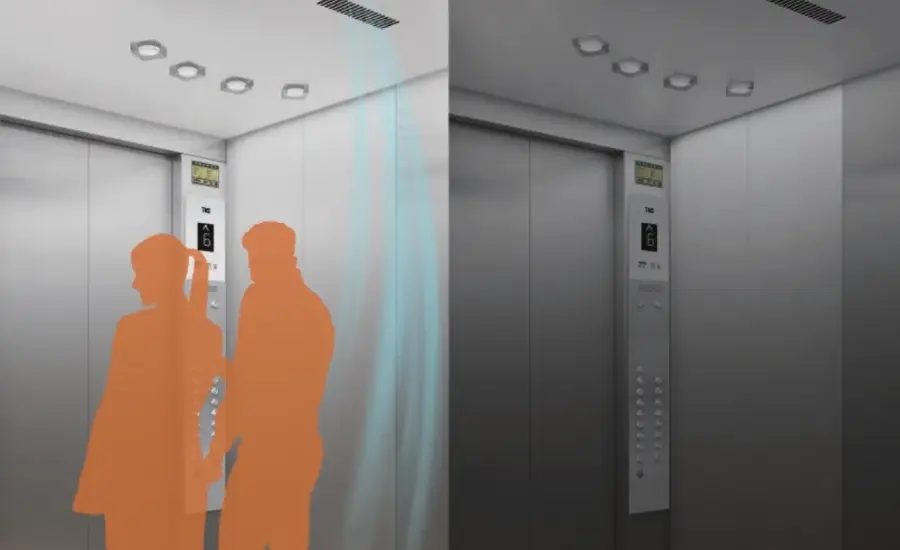

- The car visualization security system guarantees a safe ride for passengers.

- With a compact structure, the main machine is strategically positioned between the guide rail and the shaft wall, enhancing shaft utilization. The shaft area is nearly 10% smaller than the market average due to this efficient arrangement.

- Optimized traction machine suspension system reduces the top height of the shaft and the depth of the pit, enhancing on-site flexibility and reducing civil construction and steel structure costs.

- A new self-developed generation of efficient and energy-saving traction machines, recognized with the CQC energy-saving product certification from the National Quality Certification Center, was used in our elevators.

- The elevator ceiling features LED energy-efficient lighting, offering a longer lifespan and lower power consumption compared to incandescent and fluorescent lamps while providing the same level of illumination.

- The elevator is equipped with an advanced intelligent multi-level energy-saving mode. In instances of inactivity, the system will automatically power down equipment and switch to standby mode, effectively reducing energy usage.

- With a standardized design and a brief production cycle, certain components are pre-assembled at the factory and shipped for convenient on-site installation, ensuring high product precision.

- The scaffold-free quick-assembly process saves time and labour while maintaining efficiency and quality standards.

- Considerate barrier-free designs tailored for the elderly, including half-length mirrors, handrails, operation panels for the disabled, braille buttons, and night mode, provide enhanced care for special groups, offering a more humanized experience.

- Voice announcement and door opening delay function make it easier for you to enter and exit the elevator car.

- Quiet brakes ensure braking as silent as a household refrigerator, while the silent contactor further enhances the overall silence of the system.

- By integrating start-up compensation technology, high-precision vector control, and automatic calculation of the optimal speed curve, the elevator operates smoothly and steadily.

- Independent car frame structure, comprehensive sound insulation, and vibration reduction design all work together to enhance the comfort of the elevator ride.

- Several car decoration solutions have been meticulously crafted by experts, aligning with current trends and blending the realms of industry and art.

- You can choose from a diverse range of decoration materials and accessories tailored to your specific preferences and requirements.

Steps of retrofitting elevators

1、Factory production: Steel structure shaft and elevator modular prefabricated in factory

2、Factory pre-assembly: Assembly of pre-fabricated steel structure shafts, curtain walls, and elevators prior to factory departure

3、On-site lifting: Rapid elevator setup through on-site building block lifting

4、Commissioning: Fine-tuning the elevator post-installation and hoisting.

5、Acceptance: dual inspection and approval conducted by the factory and government departments after completion

China

China